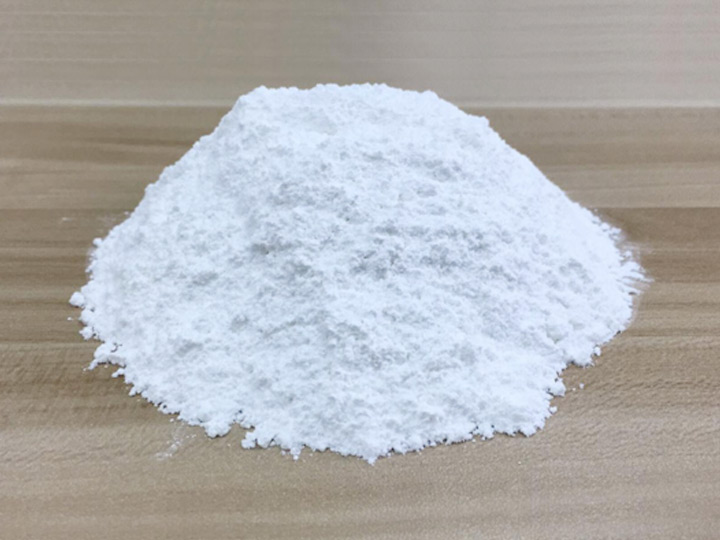

B4C (Boron carbide) powder

Sources:nanopure | Release date:

2018-08-02

| Browsing volume:

Key words:B4C (Boron carbide) powder

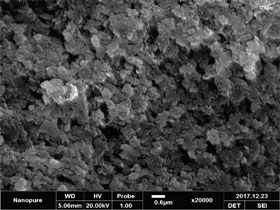

Carbothermic reduction process is an economic method to produce boron

carbide powder. In the present article this method was utilized to

produce a boron carbide powder using commercial purity raw materials.

Boric acid as a source of boron, and carbon active and petroleum coke as

reducing agents were used. Mixtures of boric acid and carbon bearing

material with a particle size of less than 44 μm were placed in a

graphite crucible and heated under a flow of argon atmosphere in a tube

furnace to 1400–1550 °C for 1–5 h. This resulted in the formation of

boron carbide powder with or without un-reacted starting raw materials.

It was found that the optimum weight ratio of boric acid to carbon

bearing material was 3.5 and 3.3 for petroleum coke and carbon active,

respectively. Heat treatment of these blends at 1470 °C for 5 h resulted

in the synthesis of boron carbide powders, which contained 0.82 and

0.59 weight percent free carbon, respectively.

B4C (Boron carbide) powder

1) 98% min & 99% min.

2) size: 0.2um

Relevant articles

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates

Related products