Processing of Boron Carbide‐Aluminum Composites

Sources:nanopure | Release date:

2018-08-02

| Browsing volume:

Key words:Processing of Boron Carbide‐Aluminum Composites

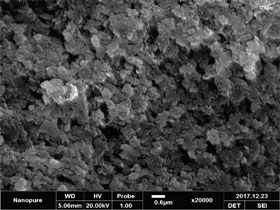

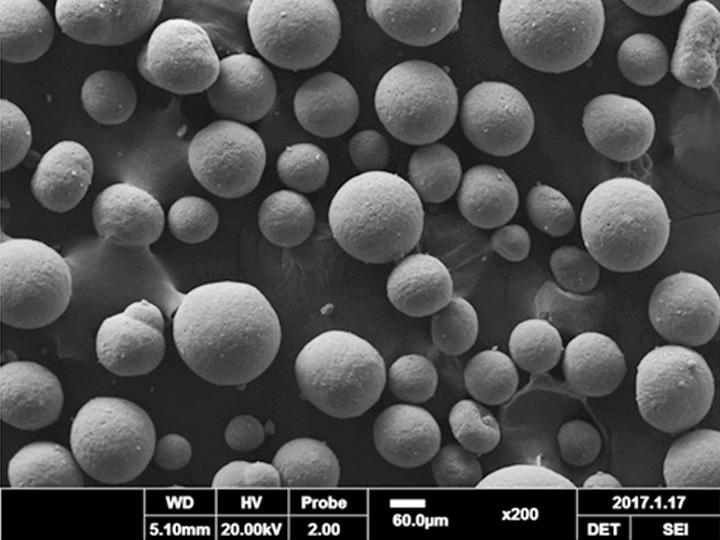

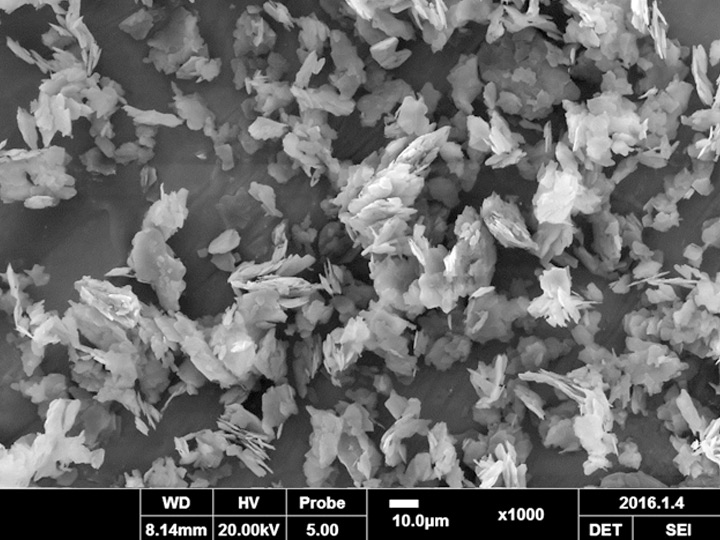

The processing problems associated with boron carbide and the limitations of its mechanical

properties can be significantly reduced when a metal phase (e.g., aluminum) is added.

Lower densification temperatures and higher fracture toughness will result. Based

on fundamental capillarity ther modynamics, reaction thermodynamics, and densification

kinetics, we have established reliable criteria for fabricating B4C–Al particulate composites. Because chemical reactions cannot be eliminated, it is

necessary to process B4C–AI by rapidly heating to near 1200°C (to ensure wetting) and subsequently heat‐treating

below 1200°C (for microstructural development).

Relevant articles

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates

Related products