Preparation of carbon-free B4C powder from B2O3 oxide by carbothermal reduction process

Sources:nanopure | Release date:

2018-08-02

| Browsing volume:

Key words:Preparation of carbon-free B4C powder from B2O3 oxide by carbothermal reduction process

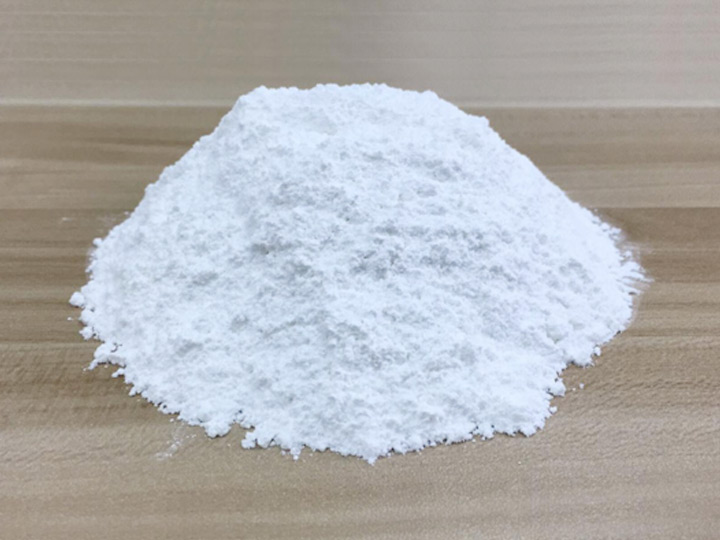

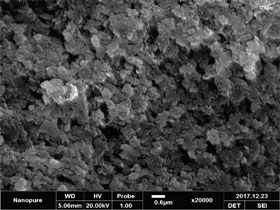

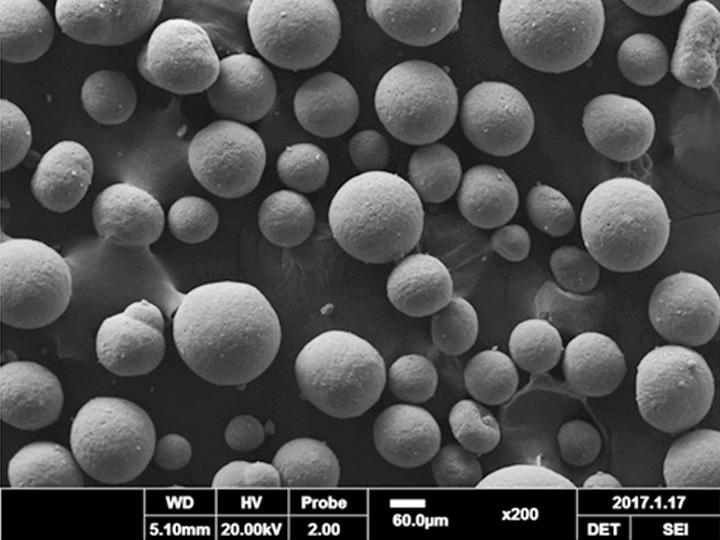

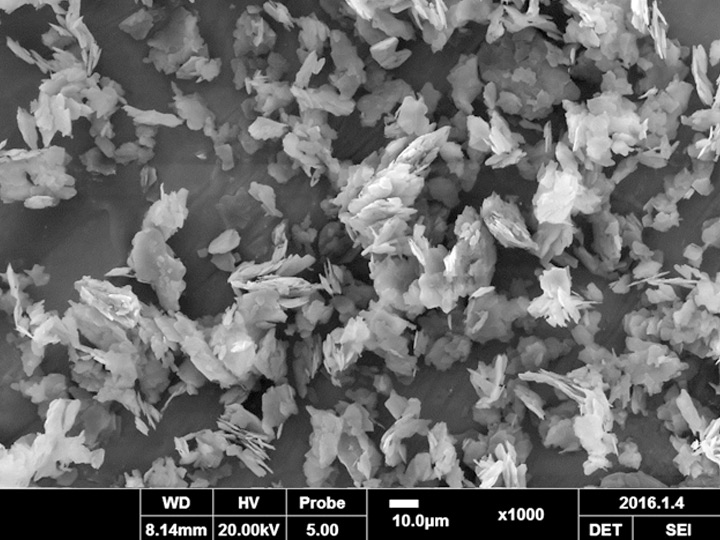

To minimize free carbon residue in the boroncarbide (B4C)

powder, a modified carbothermal reaction is performed where the

starting material compositions are adjusted. Because of boron loss in

the form of B2O2gas during the carbothermal reaction of the stoichiometric starting composition, the final B4C powders contain carbon residues. Thus, an excess B2O3is used in the reaction to compensate the loss and to obtain

stoichiometric powders. Parameters of the process for obtaining the

carbon free B4C powder by the carbothermal reduction have been determined using X-ray diffraction analysis andscanning electron microscopy. The synthesized B4C powder using a carbon-deficient composition shows no trace of carbon with two types of grain morphologies.

Previous:Lattice Constants of Boron Carbides

Relevant articles

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates

Related products