Sintering Aids in the Consolidation of Boron Carbide (B4C) by the Plasma Pressure Compaction (P2C) Method

Sources:nanopure | Release date:

2018-08-02

| Browsing volume:

Key words:Sintering Aids in the Consolidation of Boron Carbide (B4C) by the Plasma Pressure Compaction (P2C) Method

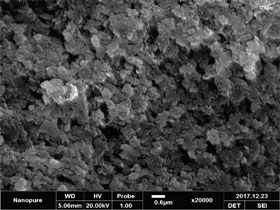

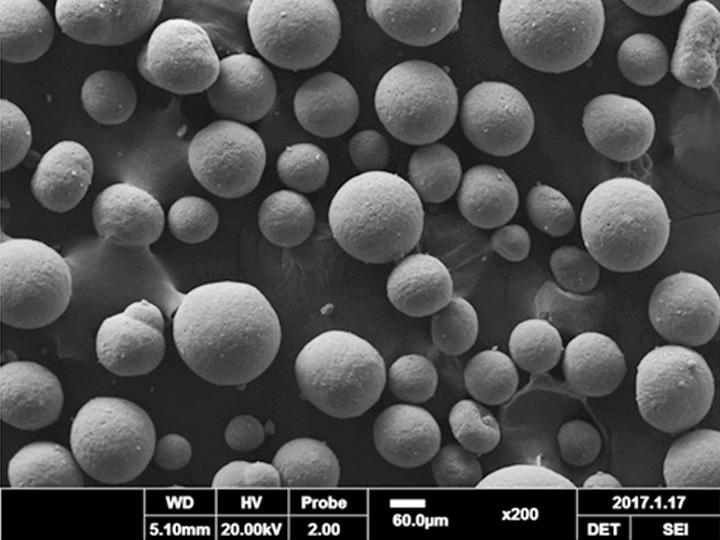

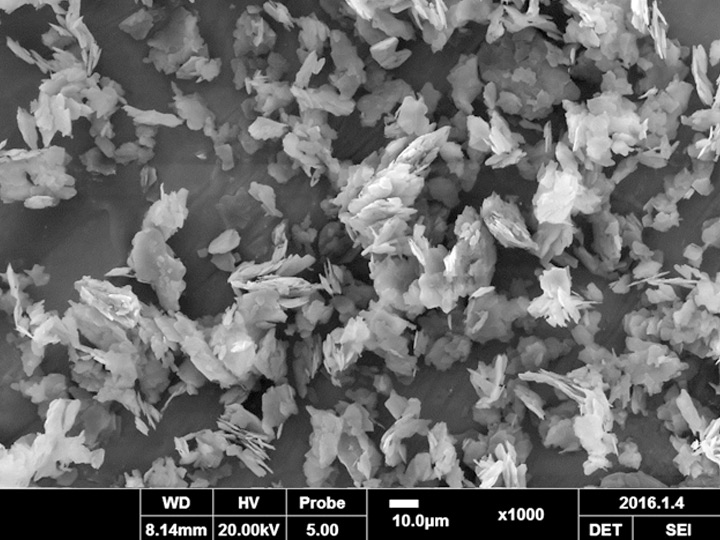

Boron carbide (B4C) powder has been densified by a novel method of powder consolidation known as Plasma Pressure Compaction (P2C). The P2C

technique allows for rapid consolidation of powder by Joule heating of

the powder bed. Powder is placed in graphite dies, and uniaxial pressure

and low-voltage, high-amperage (10 V, 5000 amps maximum) direct current

are applied to achieve densification. Pure B4C powder was

consolidated at lower temperature and hold time to densities equal to

those achieved by conventional hot pressing. With the addition of a

small amount of alumina (Al2O3) as a sintering aid, densities as high as 97% theoretical were attained.

Relevant articles

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates

Related products